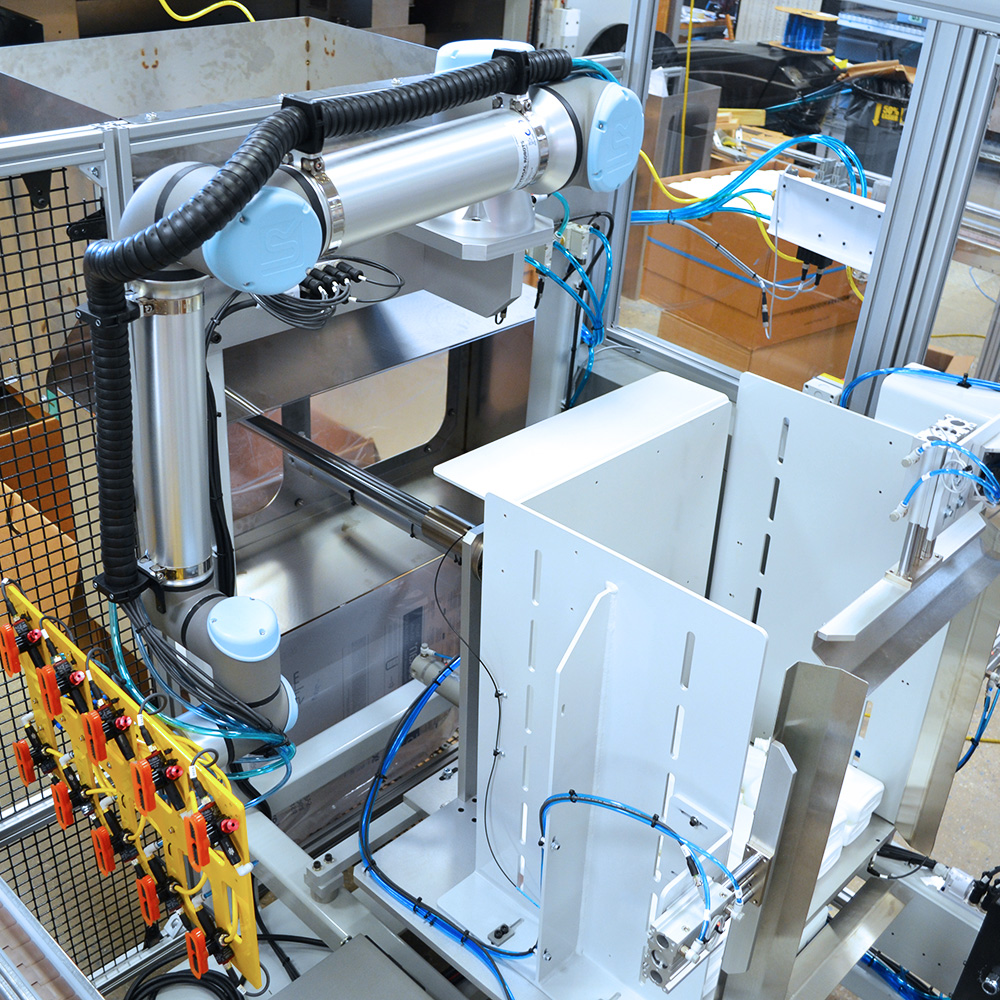

Robotic Case Packer

Automate the repetitive task of packing boxes with a collaborative robot. ONExia case packers are a flexible solution that can be easily adjusted to handle various products.

Pick and Place Packaging Robots

Customized to each application, ONExia collaborative case packers are an alternative to standard packaging automation.

- Collaborative - operates alongside humans with no physical guarding needed

- Minimal integration - requires only a 110v outlet and standard air line to operate

- No programming - custom software preloaded to product specifications on a touchscreen interface

Flexible Cobot Automation

By using a cobot, robotic case packers can be easily adjusted for product changeover.

- Custom grippers - pneumatic and electric based on product with optional quick disconnects

- Portable - optional mobile pedestal for moving between lines

- Versatile - easily integrated with vision systems for fulfillment verification and quality control

ONExia case packer robots can be combined with case erectors and palletizers to create fully automated collaborative packaging lines.

Robotic Packaging Machinery

For applications that require additional mechanical components to package product, cobots can be integrated into centralized packaging systems.

- Industrial safety - physical guarding protects the non-collaborative mechanical components

- No programming - fully customized software package operated from a single touchscreen interface

- Minimal integration - customized to fit existing in-feed and out-feed conveyor configurations