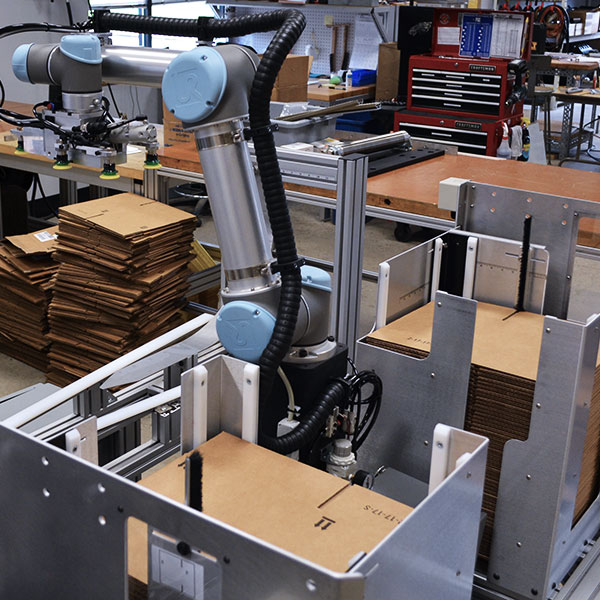

Robotic Case Erector

Using an integrated collaborative robot, ONExia case erector systems are a space saving alternative to traditional packaging machinery.

Automate Box Building with a Robot

Featuring a minimal footprint, ONExia robotic case erectors are collaborative and can be easily added to both new and existing packaging lines.

- Collaborative - operates alongside humans with no physical guarding needed

- Minimal integration - works with existing conveyor layouts and box sealing equipment

- No programming - custom software preloaded with box dimensions on a touchscreen interface

- Flexible - easily adjusted as box dimensions change

Flexible Packaging Machinery

By automating the dull, repetitive task of box building with a collaborative robot, existing labor can handle more complex tasks in the manufacturing process.

Based on production demand, multiple flat shipper magazines can be added for different box sizes.

Compact Packaging Line Design

With no caging or guarding needed, a case erector robot and case packer robot can be integrated together providing a fully automated line within in a minimal footprint.

Plug-and-play packaging automation. Simply add flat boxes to the magazine and press play, the robots do the rest!