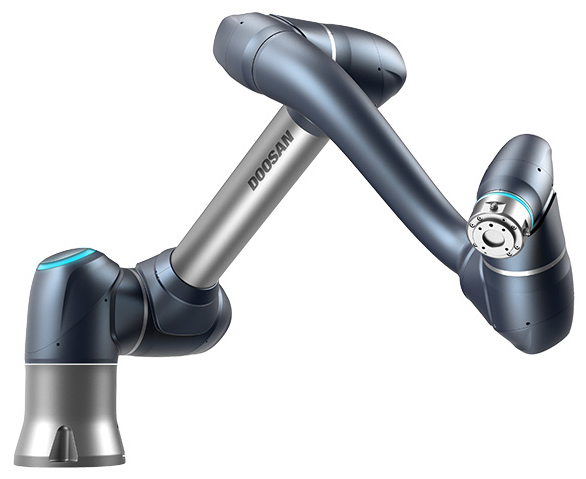

Doosan Robotics

Ideal for automating ergonomically challenging packaging processes, the Doosan Robotics line of collaborative robots are industry leaders in payload and reach.

Why use collaborative robots?

Collaborative robots or “cobots” are designed to safely operate without caging or guarding within the same work environment as human laborers.

- Cost effective – up front cost of automation is significantly lower providing a faster ROI

- Flexible – easily retooled and repurposed as production demands change

- Safe design – meet high level industry standards that assure worker safety in collaborative applications

- Easy to operate – tasks are taught through a touchscreen interface or teach pendant

PalletizHD - Robotic Palletizer

The PalletizHD is the most robust cobot palletizer on the market, automating the most ergonomically challenging line tasks.

- High payload - handle case weights up to 38 lbs, or pick multiple lighter cases at once for increased output

- Vertical reach - stack pallets over 100 inches in height

- Production speed - runs a consistent 7 picks per minute rate