Robotic Palletizer

Using collaborative robots, ONExia’s robotic palletizers require no caging or guarding to operate providing a flexible alternative to industrial packaging machinery.

Why you need a ONExia Palletizer

This is more than just a robot placing cases on a pallet.

Every robotic palletizer is designed with the features needed to automate palletizing safely and successfully using a cobot.

- Minimal footprint - no caging or guarding needed to operate

- Quick deployment - requires a 110v outlet and an air line

- Portable - built-in fork pockets within the welded base

- Multi-pallet reach - stack pallets on either side of the cobot

- Flexible design - easily adjusted for new pallet configurations

Advantages of Cobot Palletizers

Automate the dull, ergonomically unsafe task of palletizing boxes with a cost effective, robotic solution.

Minimal Footprint

By using a cobot the overall footprint of automation is comparable to the space required for manual palletizing.

Flexible Automation

Easily change out end-of-arm tooling and adjust pallet configurations without writing a line of code.

Industry Leading ROI

Cobots provide a cost effective alternative to centralized robotic palletizers providing an ROI of under one year.*

Repurpose Existing Labor

By automating palletizing, existing labor can repurposed to positions that are more difficult to automate and more desirable to work in.

*Running 3 shifts a day, actual ROI may vary based on production rates.

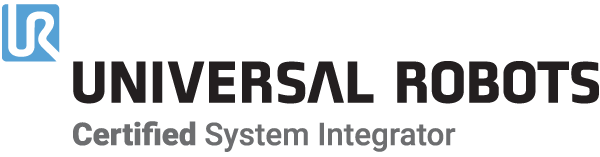

Robotic Palletizing Software

Automation without writing a line of code.

Build and save custom pallet configurations without writing a line of code using ONExia’s drag-and-drop cobot palletizing software.

- Simple interface - designed for non-technical end users

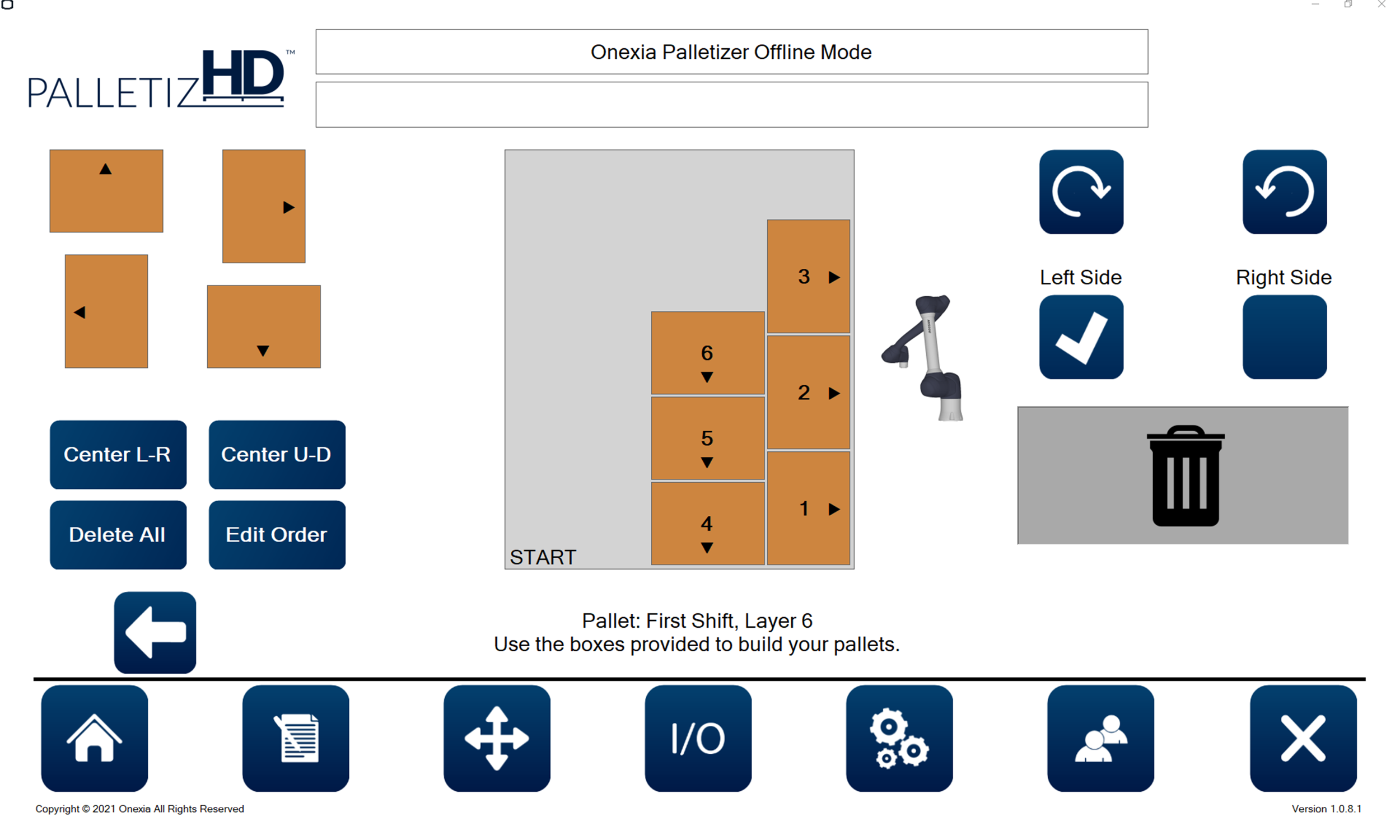

- Pallet library - build, edit, and save hundreds of configurations

- Admin controls - limit access based on user credentials

- Dual mode - tend two separate lines with one PalletizHD

Every ONExia collaborative robot palletizer comes with the palletizing software preloaded on the panel PC.

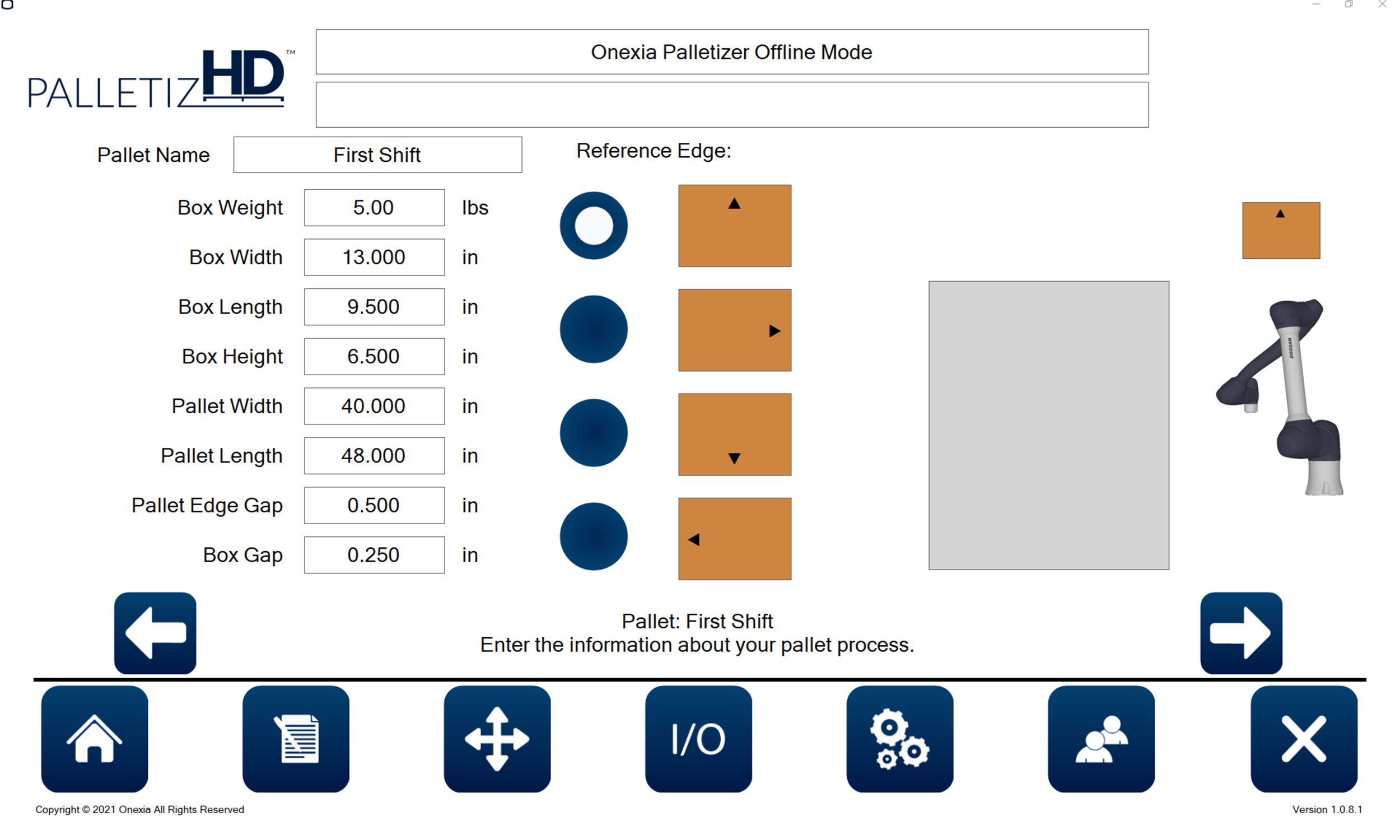

Customize Layers

- Create any layer configuration

- Orient shipping labels

- Add slip sheet between layers

Data Communication

- Signal AGVs to remove pallets

- Monitor system output in real time

- Interact with inventory software

System Functionality

- Operated through a single touchscreen

- Adjustable safety scanner zones

- Built-in conveyor controls

Collaborative Robot Specialists

10 years of cobot integration experience.

Every palletizing application is reviewed by the ONExia team of engineers and is delivered as a fully developed, production ready solution.

- Custom accessories - conveyors, grippers, and slip sheet racks designed specific to every application

- Machine safety - collaborative rated palletizers and integrated safety controls on conveyors

- Simplified software - drag-and-drop pallet building and conveyor control through the ONExia palletizing software

- Support & training - a full team of engineers to assure a successful cobot deployment

Collaborative Robot Safety

Designed and built by ONExia Inc. in Pennsylvania, every palletizer features a collaborative safety rating.

Using collaborative robots from industry leading vendors and safety rated components, ONExia robotic palletizers have been reviewed by a third party and conform to the safety ratings necessary to run unguarded within palletizing applications.

End-of-arm Tooling

Designed specific to each application, every ONExia Robotics Palletizer comes with the end-of-arm tooling needed to assure your cobot deployment is successful.

- Dedicated vacuum pumps – in line with every suction cup for maximum vacuum capacity

- Dual pick functionality – pick two cases at once for increased cycle time

- Vacuum sensors – assure pick is successful prior to moving over the pallet

- Tool changer – easily interchange grippers without powering down the system

Custom In-Feed Conveyors

Designed to work with existing conveyor layouts, ONExia’s nesting systems provide a flexible pick point that is controlled through the palletizing software.

- Hand adjustable guide rails for single and dual pick options

- Pneumatic nest controlled through the palletizing software

- Indexing sensors to eliminate back pressure

- Integrated e-stop for end-user safety

- Plug and play design with a ONExia palletizer

A Single Point of Purchase

Simplify the buying process by working with ONExia.

Partnered with industry leaders of conveyors and stationary machinery, ONExia delivers fully integrated, turn-key packaging lines through a single Purchase Order.

- Conveyors - custom configurations integrated with indexing and safety controls

- Case sealers - selected based on end-user specification

- Vision systems - fully integrated bar code readers and quality control inspection solutions

PalletizHD - Robotic Palletizer

The PalletizHD is the most robust cobot palletizer on the market, automating the most ergonomically challenging line tasks.

- High payload - handle case weights up to 60 lbs, or pick multiple lighter cases at once for increased output

- Vertical reach - stack pallets over 96 inches in height

- Production speed - runs a consistent 7 picks per minute rate

PalletizUR - Collaborative Palletizer

A turn-key palletizer designed for Universal Robots that requires no programming to operate.

- Integrated Universal Robots cobot arm

- Drag-and-drop pallet building on a touchscreen interface

- Fully collaborative, no caging or guarding required